The Results

By adding a smartwatch to the PPE (Personal Protective Equipment), managers were able to:

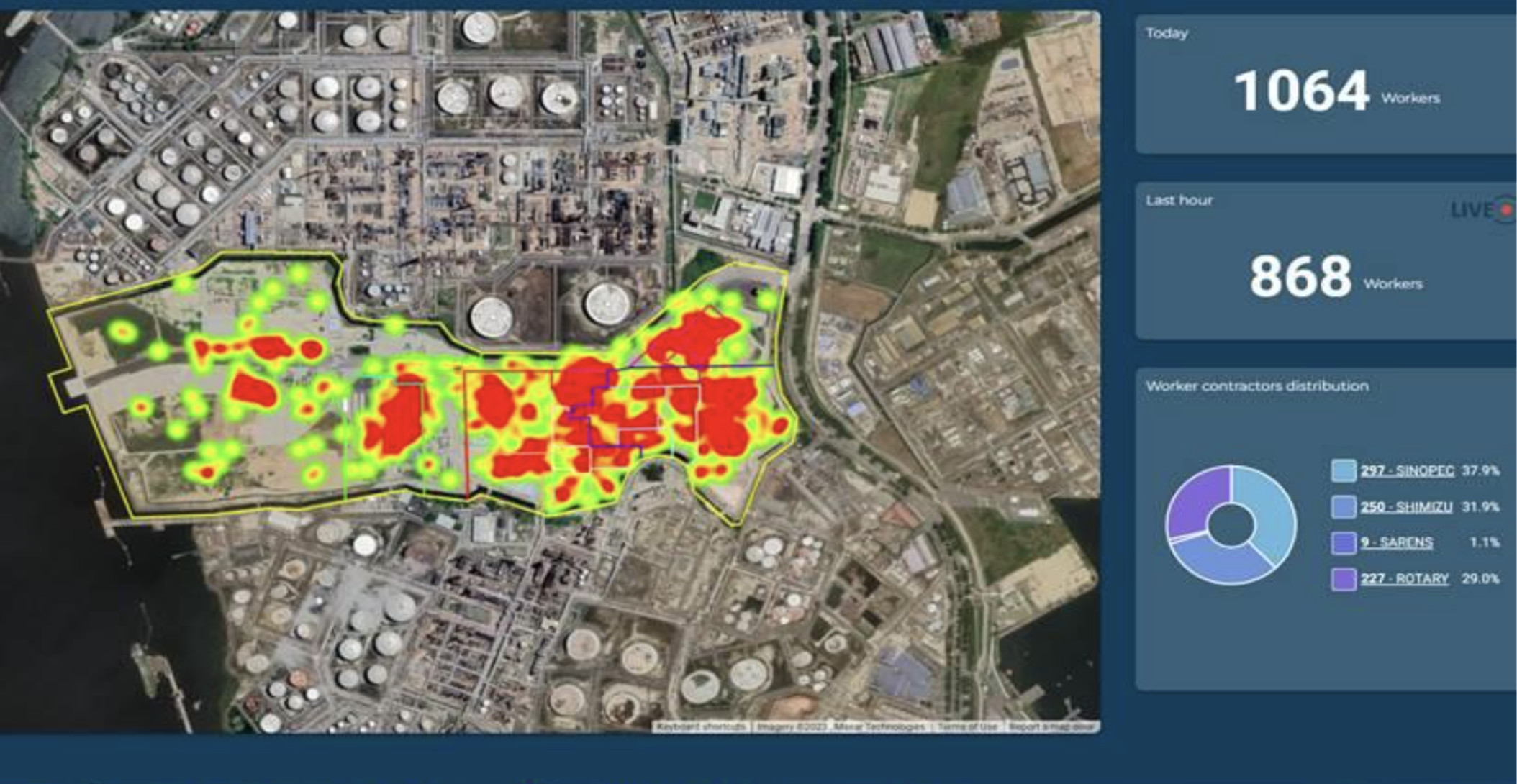

- Reduce non-authorized access by 20%

- Detect 50-100 hazardous areas daily

- Develop an effective emergency response plan

- Reduce staff by 5 security guards

- Generate daily training and overwork reports

This comprehensive solution prioritized worker safety, convenience, and seamless integration, ultimately contributing to a safer work environment and improved operational efficiency.

"Improving access control not only represents an important achievement from the productivity perspective, but also it positively impacts the safety of the most important assets in any organization: human resources. Digitalization and implementation of HSSE solutions contribute significantly to reducing the accident rate and positively impact on companies' bottom lines.", said Javier Benjumea Serra, CEO of WILOC.

The results of this IoT case not only benefit the company, but also contribute to achieving three of the United Nations' seventeen sustainable development goals (SDGs).